1. Tool Design & Construction

2. Production

3. Secondary Surface Processing

4. Roboter assisted Assembly

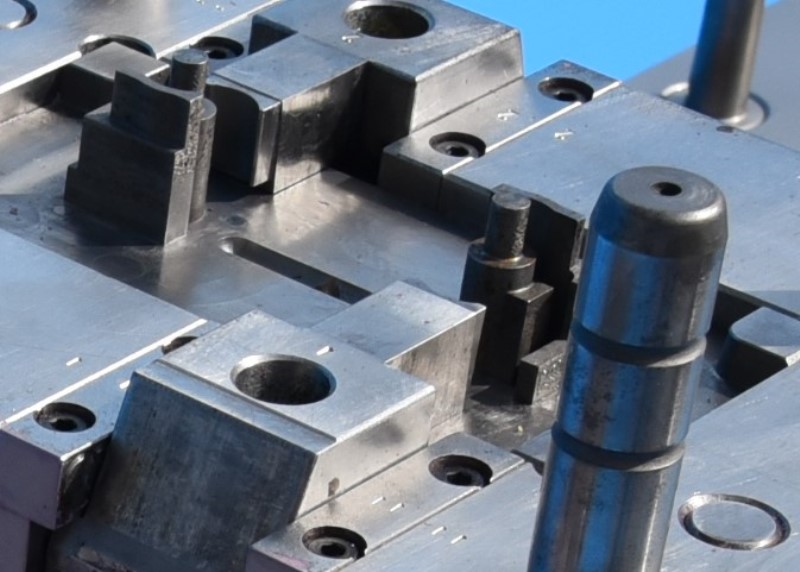

Tool design & tool making

A specialized team ensures high quality customized tool making, fast response time and necessarily maintenance. Close cooperation with production, raw material experts and customer is the foundation of reliable and stable product performance over life time of the project. Trust and safety that you can rely on DO make the difference! |

Technology Production

|

Design

|

Accurate design for high quality product. The perfect design is a fundamentally important factor witch controls both the function and the quality of the final part. It guarantees the function which the assembly during the project life time. Based on vast experience and a large database having built over 5’000 successful projects enables Abatek to design the product that suits your requirements best. |

|

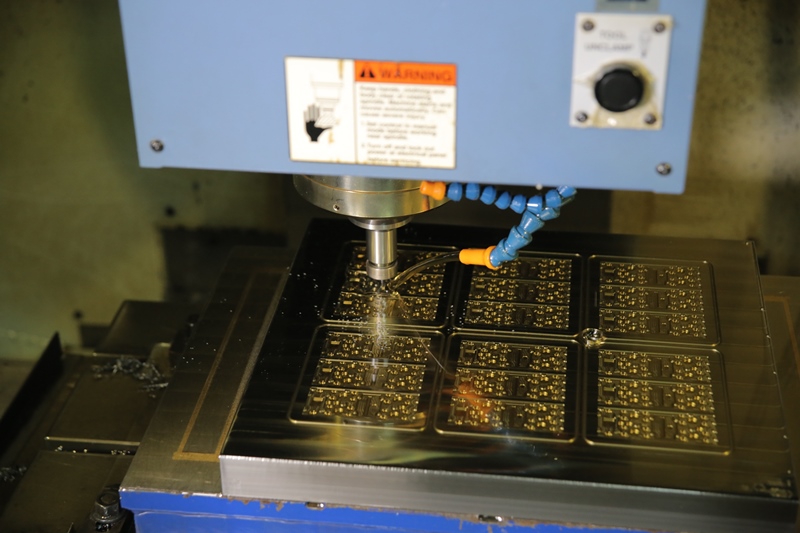

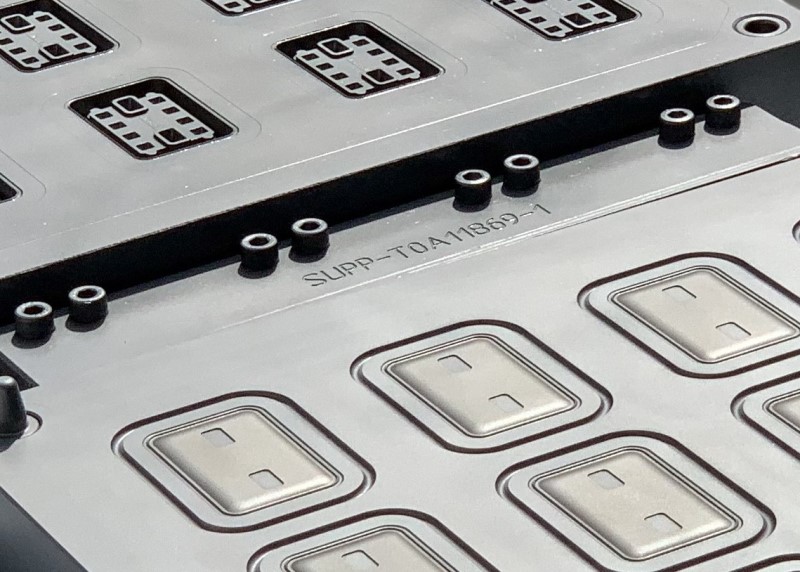

Tooling

|

Own tool shop guarantees full control and efficiency. Modern machine infrastructure guarantee high quality and environment friendly production of precision tools. Abatek is your reliable partner starting from the design all the way to the fulfilment of your automotive, medical, consumer, instruments, telecommunication or any other solution. |

|

Production

In-House control along the entire value chain ensures maximum process stability. Abatek has extensive material knowledge and experience regarding proper application. Abatek successfully strives for steady improvement and ongoing training. |

Technology Production Tab-Compression-molding

|

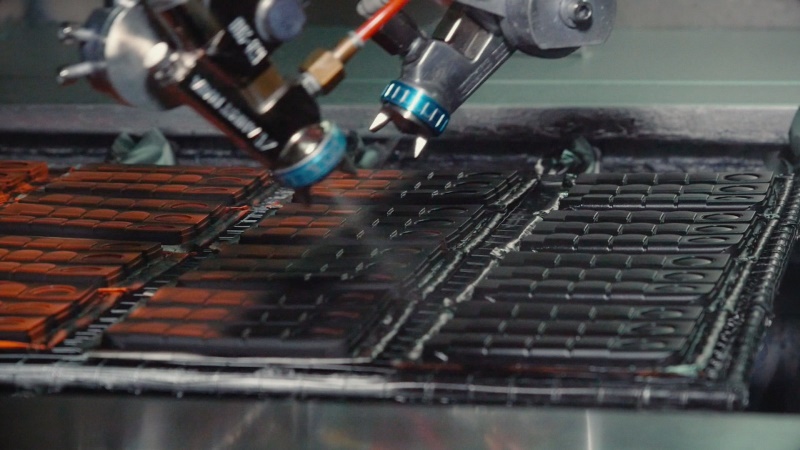

Compression molding

|

Essential for most parts. Most elastomers / silicone keypads are produced using a 2 layer compression mold which works very similar to a professional “waffle production”. For more complex parts tools can have up to 5 layers. By using optimal pressure, temperature and time the perfect part is produced. |

|

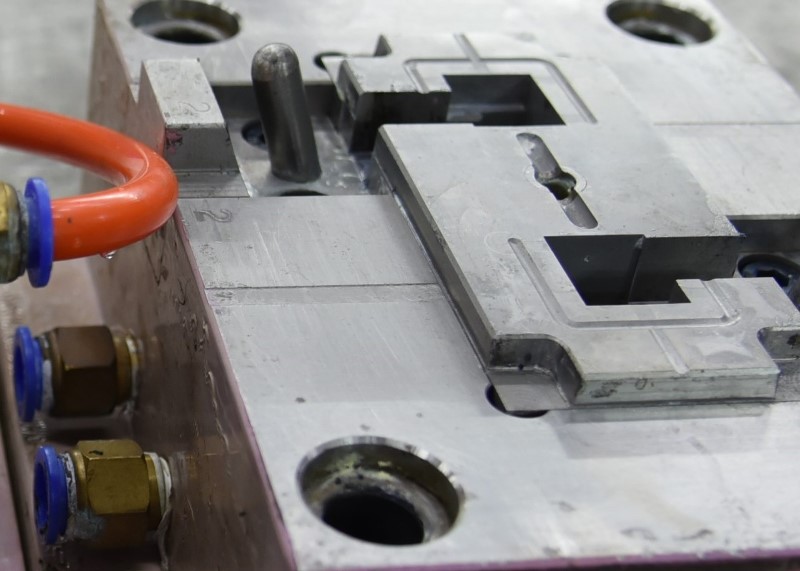

Transfer molding

|

Ensure highest efficiency. Transfer molding starts with a closed tool and the material being injected. The rest of the process is identical to compression molding. Some shapes made out of elastomer / silicone are more efficiently produced using the suitable transfer molding technique. Abatek will always chose the most efficient process to ensure the best commercial offer. |

|

Injection Molding

|

Traditional injection molded parts for higher quantities. Injection molding is a formative manufacturing technology. In order to create desired parts polymer compounds are firstly melted and then injected into the cavities of the mold. Abatek will always chose the most efficient process to ensure the best commercial offer. |

|

Reaction Injection Molding

|

Strong, flexible, lightweight parts with RIM. The Abatek self-healing surface named Polyform3D is made out of Polyurethane and produced via Reaction Injection Molding (RIM) technology. The polymer mixture is injected under pressure into a closed mold. It remains closed until the part is cured. |

|

Secondary Surface Processing

The exclusive Abatek coating Sealplast® assures longest possible product lifetime for any decorative silicone part - also for outdoor applications. |

Technology Production Surface

|

Spray processes

|

Coloring the part. To mark or color parts Abatek offers various In-House spray options:

|

|

Printing

|

Customized printing. Almost any color or design can be applied to the surface using silk screen printing, pad printing or ink printing. |

|

Lasering

|

Enlighten or mark the parts. For lighting or coloring options silicone parts can be lasered. |

|

Coating

|

Sealplast - exclusively by Abatek. Sealplast is developed and exclusively offered by Abatek. It is the best protection against abrasion and aggressive chemicals for silicone surfaces. Treated surfaces are available from matt to semi-glossy. |

|

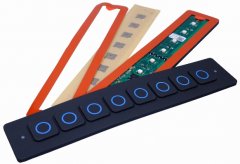

Assembly

Typical product combinations are made of plastic's, PCB's, metal and elastomer's. Thanks to the automated assembly Abatek can ensure reliable and high quality product during project life time. |

Technology Production assembly

|