This soft silicone rubber combines great technical properties.

It transfers heat through thermal conductivity, has constant properties and is fire resistant.

It can also serve as a cushion/distance keeper protector being one or two side adhesive.

Depending on the application choose Abatek ACRYLIC pad, SILICONE pad or PHASE CHANGE each representing an easy to install solution.

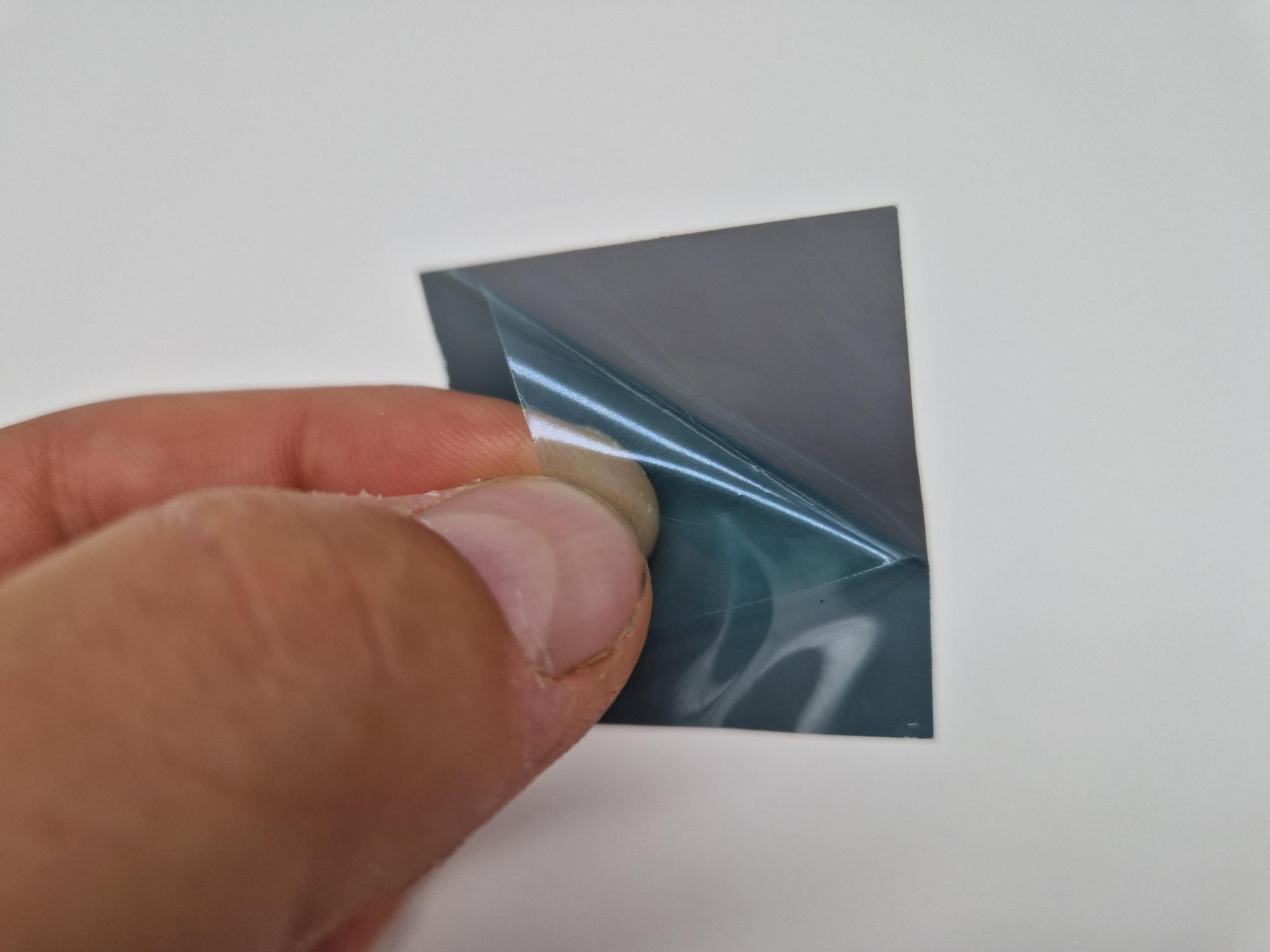

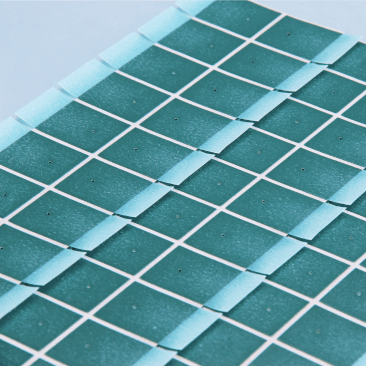

ACRYLIC THERMAL PAD (ABA)

OPTIMAL Acrylic Thermal Pad is a heat-conductive material made from acrylic-based compounds.

The ABA Acrylic Series has excellent mechanical and physical characteristics.

Enjoy design freedom for various other applications. Even jointing applications are possible.

MAIN ADVANTAGES

- No silane volatilization

- No silicone oil precipitation

- Excellent flame retardance

- Good electrical insulation

- High tensile strength, high elongation

- Medical Industry non-silicone

APPLICATION

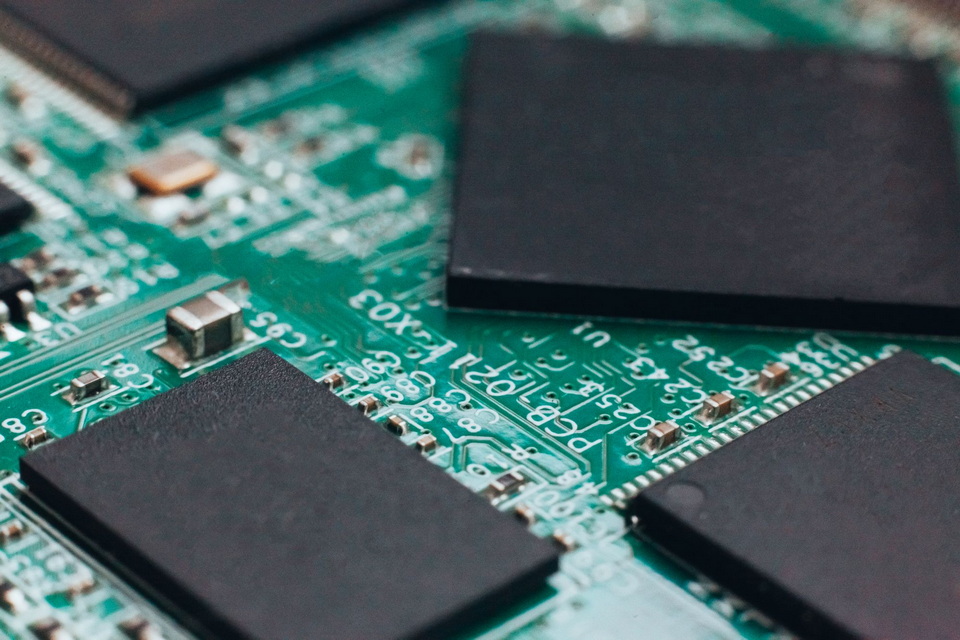

- Power battery pack

- Vehicle navigator

- Optical precision and camera equipment

- Notebook computer

- Mobile and communication

- Automotive engine control equipment

- High end industrial control and medical electronics

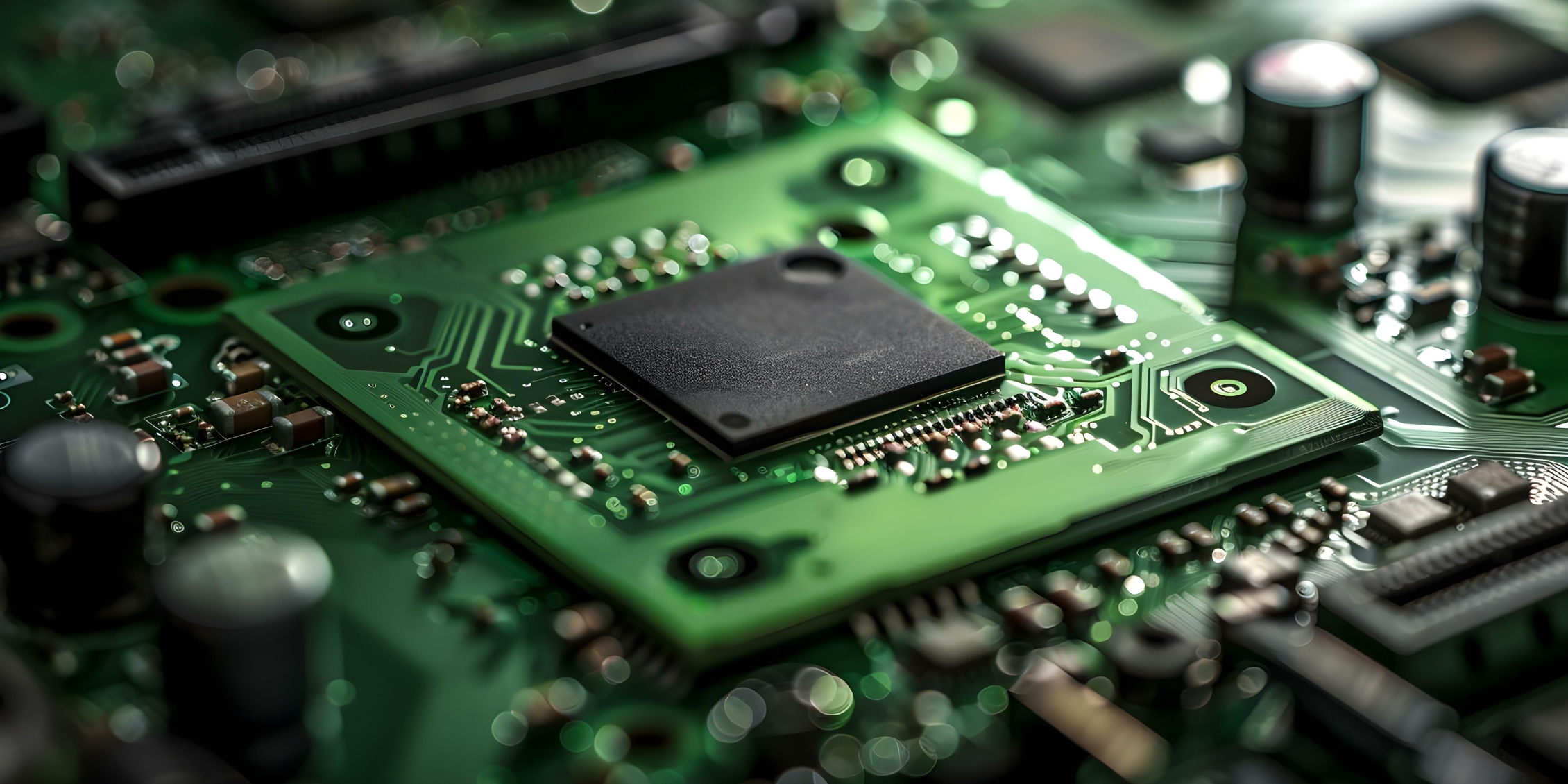

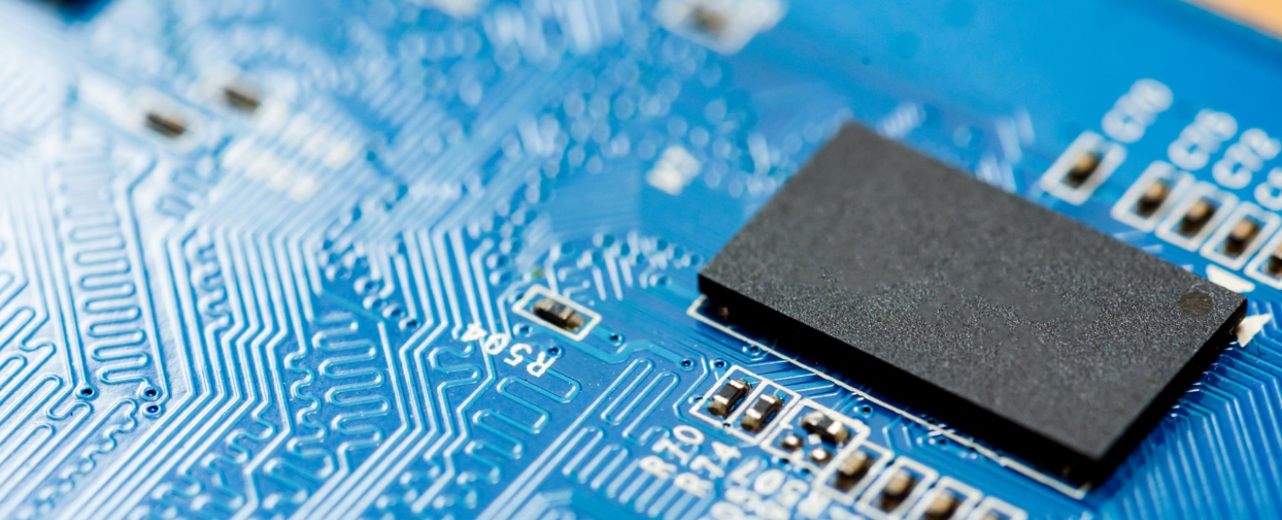

SILICONE THERMAL PAD (ABS)

OPTIMAL ABS Silicone Thermal Pad are used for filling both contact surfaces.

Consequently the pads are ultra soft and have great resilience!

Important: the pads very effectively exclude air from the crucial contact interface.

MAIN ADVANTAGES

- Excellent flame retardant

- High electrical insulation performance

- Great flexibility

- Great pression ratio

APPLICATION

- Window lift

- Steering wheel

- Start & stop / HVAC

- Head unit

- Seat adjuster

- Keyfob

- Payment terminal

- Remote controle

- Selector switch

- Telecom

- and more

DOWNLOAD

Catalogue

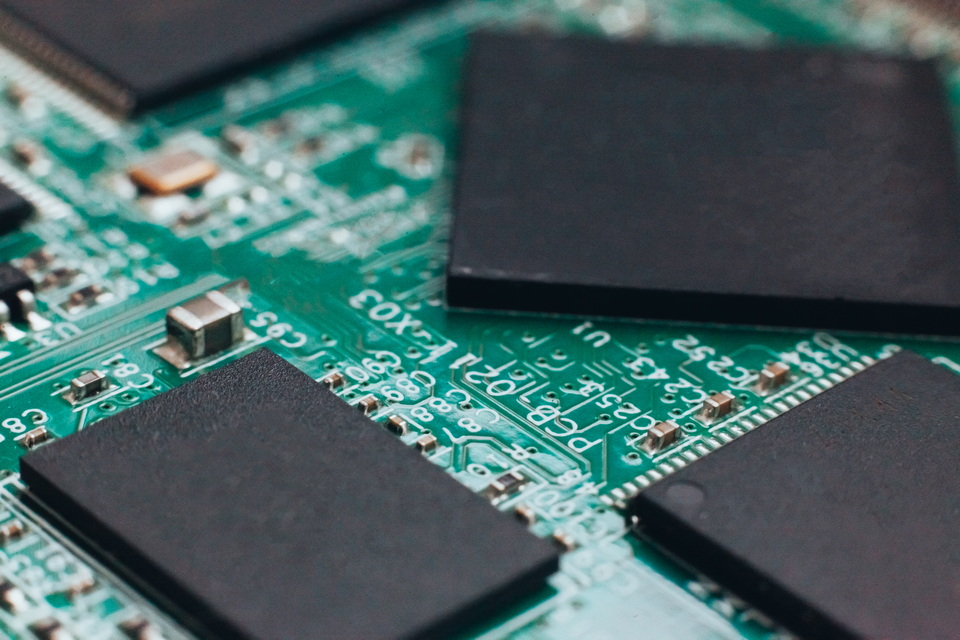

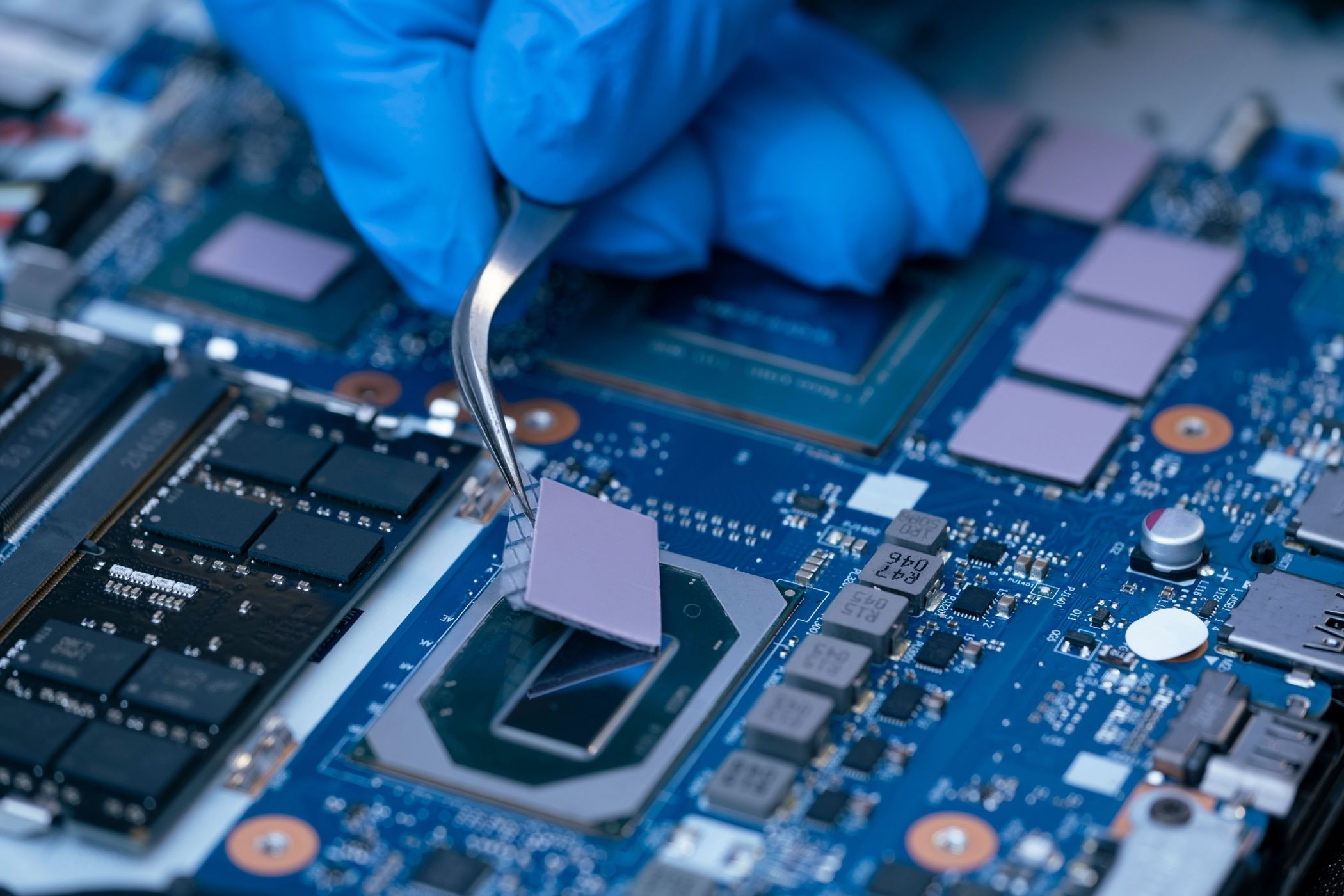

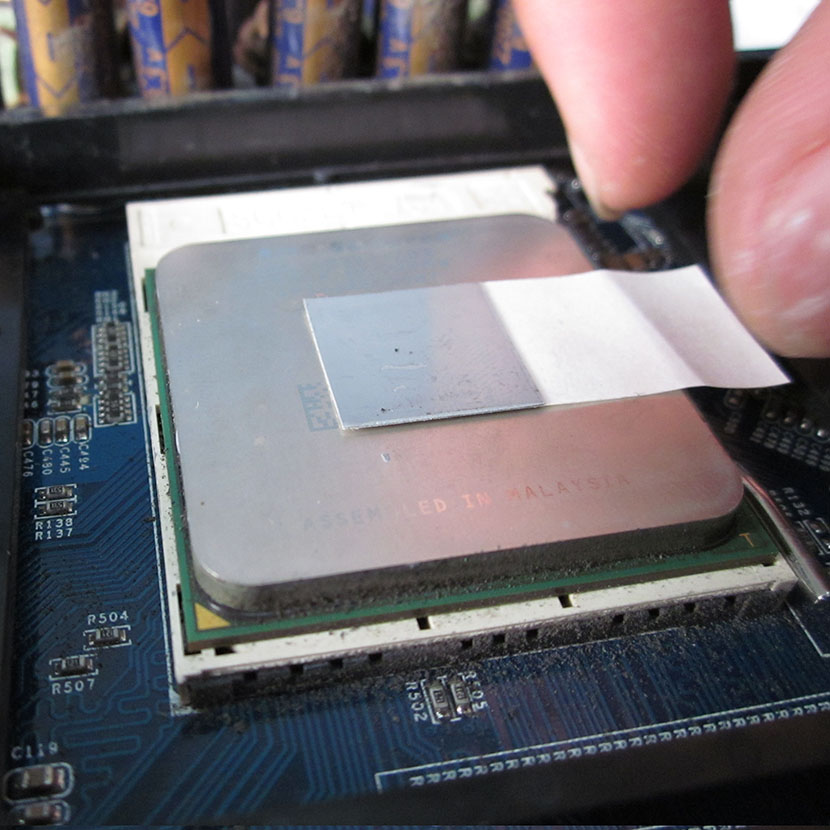

PHASE CHANGE (ABP)

OPTIMAL ABP softens at 50-55℃.

Once in a liquid viscous state, ABP fills and covers gaps and pits between contact interfaces more efficiently than thermal pads.

Important:

OPTIMAL ABP is solid at room temperature!

Assemble and use accordingly.

MAIN ADVANTAGES

- Strong interface wetting ability

- Long-term reliable thermal conductivity

- Fills the gap between given interface

- Removes air between given interface

- Sustainable over life cycle

- Makes phase transition temperature controllable

APPLICATION

- Integrated chip LED lighting products

- High frequency microprocessor

- Stationary or mobile computer

- Computer server and storage

DOWNLOAD

Catalogue

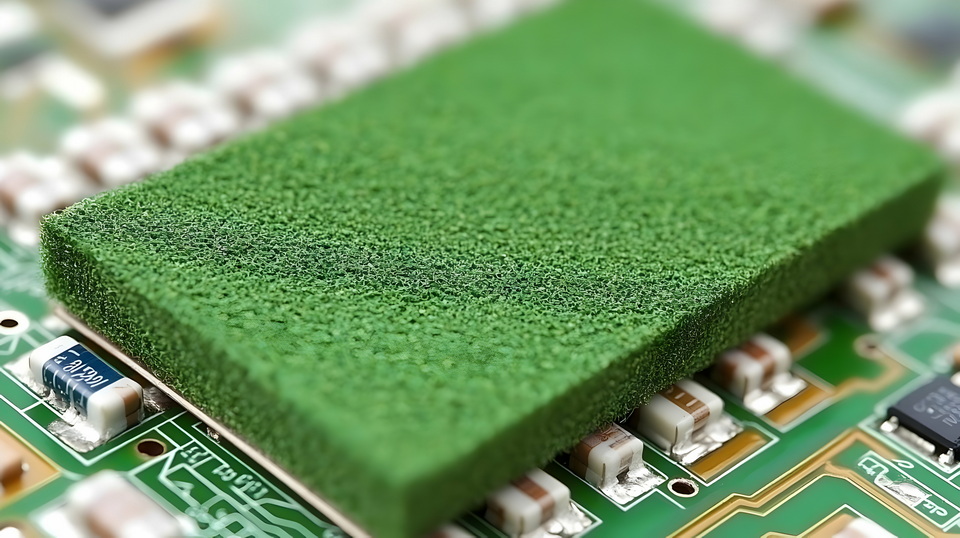

GRAPHITE FOAM (ABG)

The Graphite foam has outstanding properties! This flexible solution stands out for high conductivity and safety.

The char layer creates a MASSIVE reduction of common side effects like mass loss, gas emission and other unwanted chemical reactions.

The technical profile makes it interesting for a variety of applications within automotive, medical,

transportation (trucks, planes etc) and other temperature sensitive applications.

MAIN ADVANTAGES

- Very heat resistant

- No melting or dripping

- Great fire resistance

- Little mass loss

- Fewer emissions

- Lightweight

APPLICATION

Generally spoken: wherever density and fire safety is required:

- Automotive

- Aviaton

- Train or bus

- Furniture